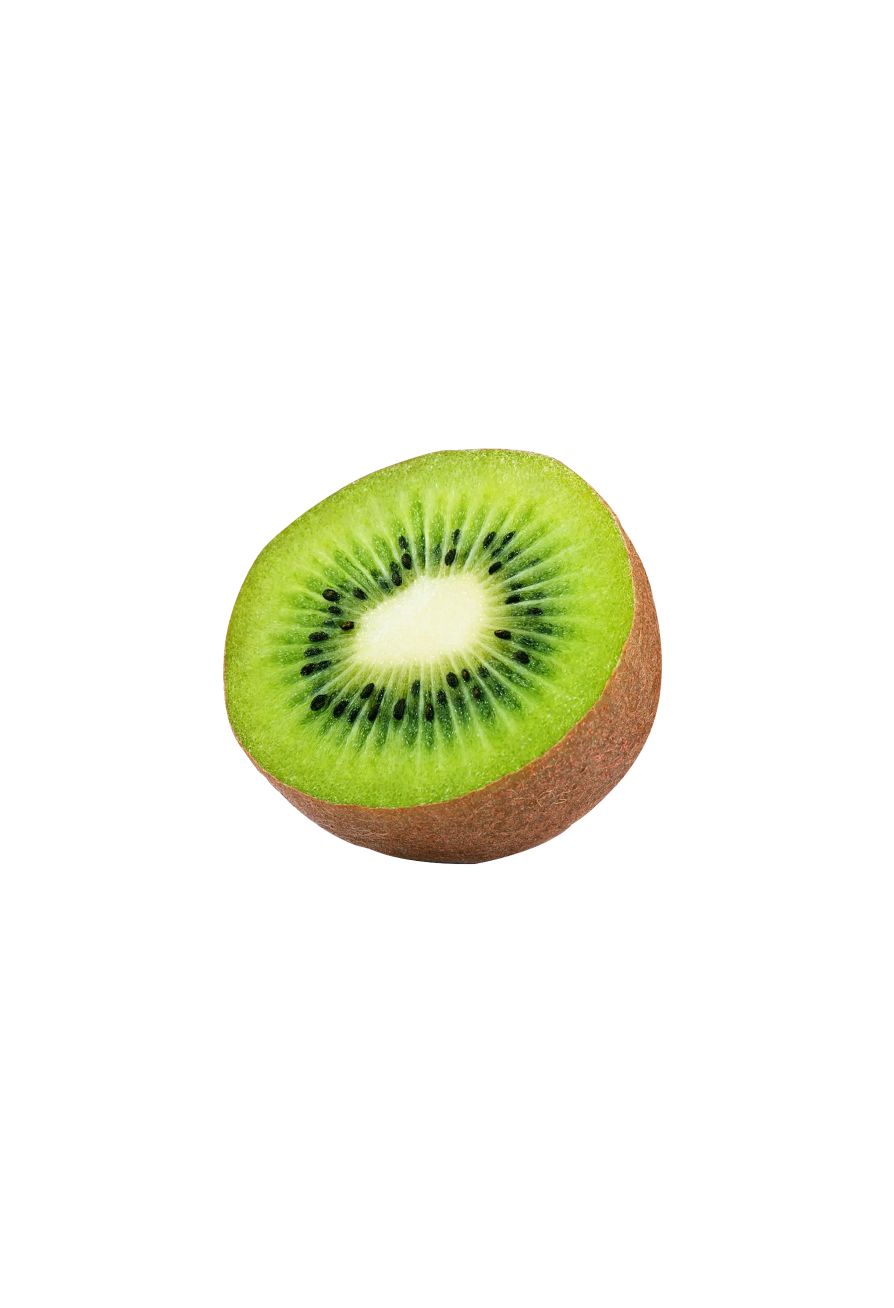

The fresh produce supply chain has invested heavily in modern, more effective temperature monitoring and control systems. This has enabled fresh produce to be transited and stored at optimum consistent temperatures. In addition, moisture loss is managed through tailored packaging solutions that maximise humidity. By addressing these elements fresh produce is now able to travel greater distances, achieve improved quality scores with reduced wastage rates. Resulting in many seasonal fruits and vegetables from home markets now available all year round.

Although much progress has been made wastage rates still remain stubbornly high. A major, but difficult to measure driver of this waste is ethylene – the plant ripening hormone. Moderation of ethylene is vital to both extend fresh produce life and enable it to develop to its optimum. As a factor it is frequently overlooked or controlled in a suboptimal way which either inhibits it’s action outright or doesn’t reduce levels enough to improve shelf-life. This also means that it is rarely monitored even though in many fruits and vegetables once temperature and modern packaging profiles are managed this is the outstanding element to address.

Justin Creasy It’s Fresh Technical Services Director said: “I oversee multiple arrivals of produce, but have never seen accurate measurement of ethylene due to how difficult it is to do so. Portable Ethylene readers exist, however I have never come across one that is specific to ethylene, measuring instead a combination of volatiles, meaning any reported number is not attributable to ethylene. In our laboratory, we have two purpose-built ethylene Gas Chromatography (GC) Analysers that measure ethylene very precisely – to concentrations below 20 parts per billion.”

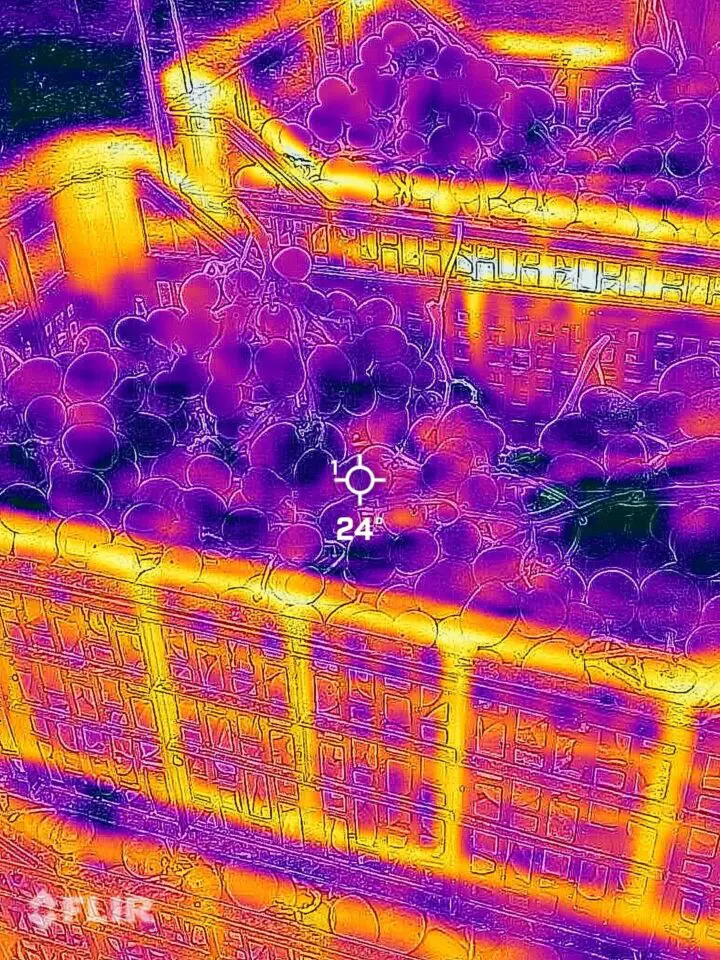

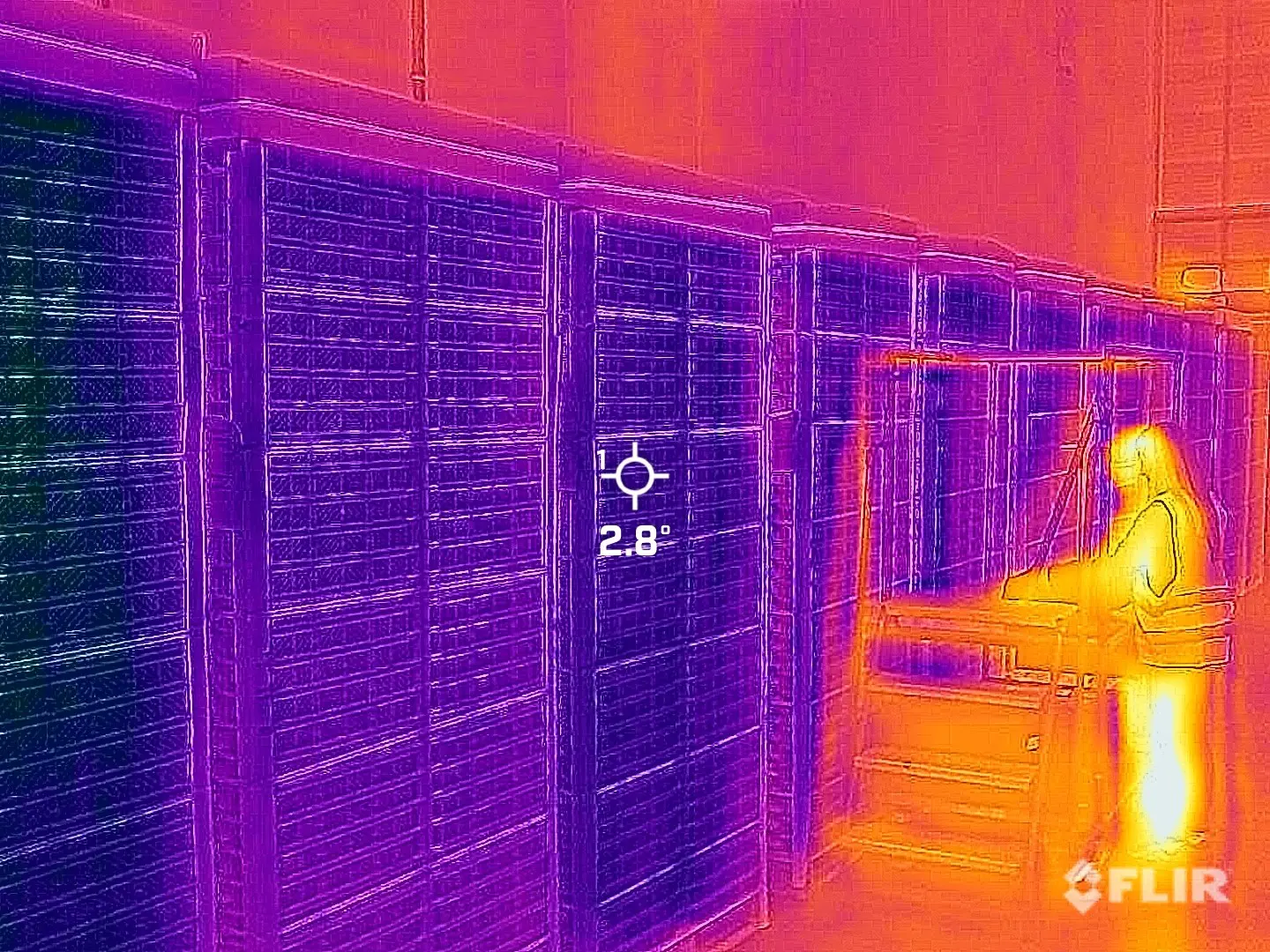

“Interestingly with an Infra-Red camera you can see ethylene – or more precisely the impacts of it. Pallets with poor air flow and lack of ethylene management have a localised build-up of these molecules. This triggers increased respiration which in turn manifests in higher local temperatures – this causes the goods to produce yet more ethylene. An Infra-Red Camera visualises these hot spots on arrival, which are often accompanied by uncontrolled ethylene levels and concurrent issues with pressures and other quality attributes.”

With better ethylene monitoring within the fresh produce supply-chain, unexplained quality issues can be better understood, driving improvements such as the implementation of RYPEN Packaging solutions. As a company we have undertaken extensive commercial trials across many cultivars. Seeing the improvement RYPEN offers to our customers makes us confident that our ethylene moderating technology is the final element.